BioRemove 5190 Improved Plant Stability at Chemical Manufacturer

The application of BioRemove 5190 to the wastewater treatment system of a chemicals manufacturer led to significant improvement in plant stability.

Benefits

- Improved plant efficiency as final effluent became independent to influent loading fluctuations

- Dramatic reduction in effluent COD

Background

A chemicals manufacturer experienced regular plant upsets at their 18200 m3/d (4.8 mgd) wastewater treatment plant, due primarily to highly variable influent wastewater conditions. Historical operating problems included poor settleability (bulking) of the activated sludge biomass, high polymer usage in the secondary clarifiers, and effluent COD excursions. The plant was interested in a bioaugmentation program to increase plant stability.

Application

A technical service group performed a treatability study to quantify and predict the potential impact that bioaugmentation would have on the plant effluent prior to offering a trial. Respirometry was used to quantify improvements in biokinetic constants achieved through bioaugmentation, and activated sludge modeling was used to predict the impact that the bioaugmented rate constants will have in a full-scale plant. The study determined that the wastewater was inhibited and predicted that a biomass bioaugmented with BioRemove 5190 would reduce the average plant effluent soluble COD by 32.6%, as shown in Table 1.

| Predicted Average Effluent Soluble COD Loading Non-Augmented Vs. Bioaugmented | ||

|---|---|---|

| Non-Augmented | Bioaugmented | Expected % Reduction |

| 658 kg/d (1447 lb./day) | 443 kg/d (975 lb./day) | 32.6 |

Table 1 Both sets of kinetic constants (non-augmented and augmented) were used to predict the average soluble effluent COD loading.

| Actual Average Effluent Soluble COD Loading Non-Augmented Vs. Bioaugmented | ||

|---|---|---|

| Pre-Trial Period | Trial Period | Actual % Reduction |

| 593 kg/d (1304 lb./day) (non-augmented) | 458 kg/d (1007 lbs/day) (bioaugmented) | 22.8 |

Table 2 Actual reduction in effluent soluble COD loading. Trial data is compared with the 3-month period directly preceding the trial.

Results

The results in Table 2 show that the prediction based on the bioaugmented rate constants closely approximates the actual average effluent soluble COD loading seen during the trial (443 kg vs. 458 kg [975 vs. 1007 lb./day], respectively). When compared to the 3-month period preceding the trial (March 1—June 3), the bioaugmented biomass reduced the effluent soluble COD loading by 22.8%, with no significant change in influent COD loading.

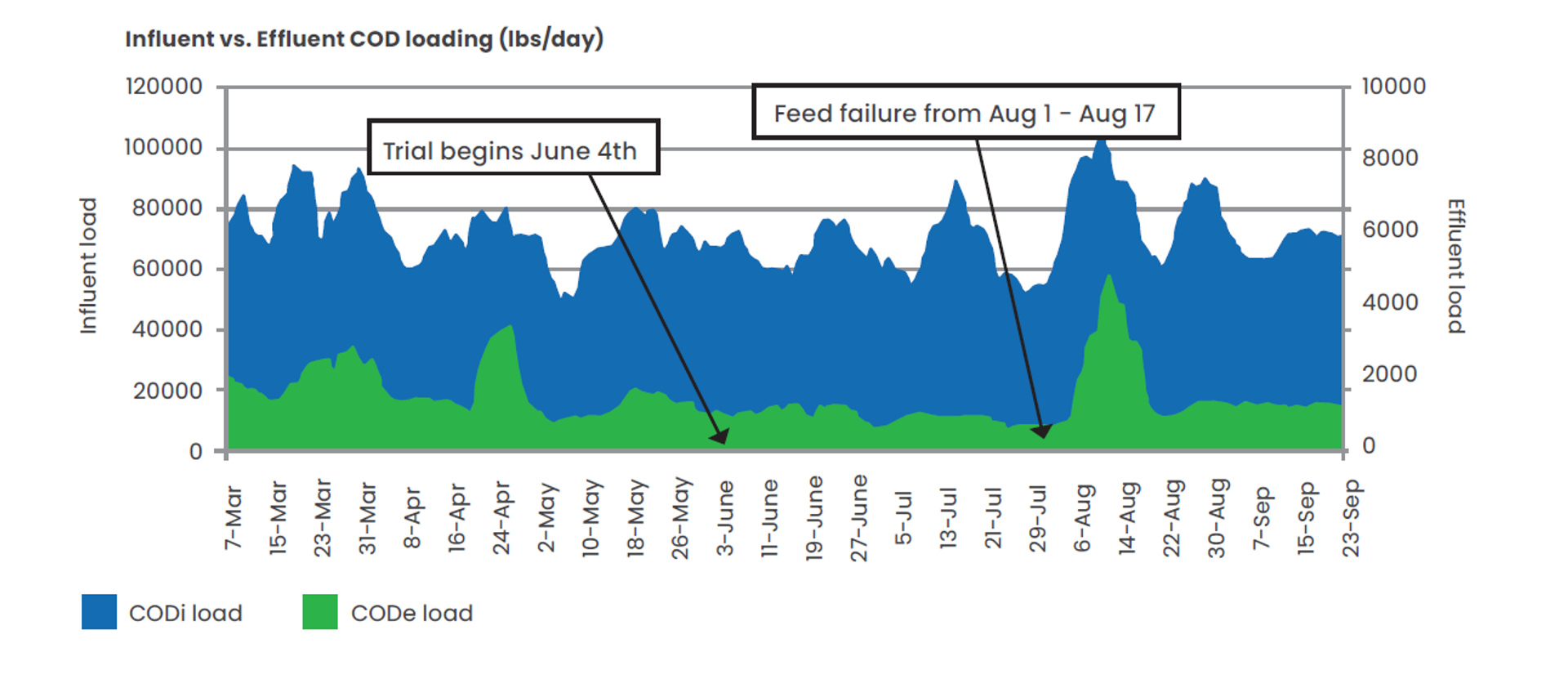

The above chart tracks the influent and effluent COD loadings over a 7-month period. The highly variable influent COD load typifies industrial wastewater (the standard deviation for the charted data is 19,364 kg/d [22,800 lb./day], while the plant influent COD load averaged 32,000 kg/day). The effluent curve (light area) during the pre-trial period exhibits similar variability and is characteristically sensitive to sudden influent COD fluctuations.

Following the start-up of the bioaugmentation program, plant stability increased to the point that effluent loading became relatively insensitive to influent loading fluctuations, as evidenced by the flattened effluent COD curve. A single, notable exception is seen during a feed equipment process failure that occurred from August 1-17. The failure coincided with a shock load that was accompanied by a threefold increase in the effluent COD load. It is particularly notable that shock loads were not accompanied by significant increases in effluent COD, or in other manifestations of plant upset such as reduced biomass settleability or increased polymer usage. None of the shock loads were hydraulically related—the average flow for the entire month period was 18,030 m3/d (4.76 mgd).

Other operating benefits to the plant were realized in addition to the dramatic reduction in effluent COD. The sludge volume index (SVI) trended downward during the trial. In addition to lower SVI, enhanced flocculation improved the solids’ capture of the settling biomass and resulted in zero polymer usage during the entire trial period. Plant operating personnel correlated the enhanced flocculation with the increase in the number and diversity of the ciliated protozoa. Ciliates are bacterial grazers whose type and numbers are indicative of the health of an activated sludge biomass. It is important to note that there is not a significant increase in the solids’ residence time of the system during the trial.

The biological program was easy to implement and provided significant benefits over other disposal alternatives, improving plant stability significantly. BioRemove 5190 resulted in:

- Improved plant efficiency

- Simplified operations

- Lower operating costs