French Fry Factory Sludge

Wastewater generated from food production can be a major source of environmental pollution and is difficult to manage because of the abundant amount of organic carbon and suspended and dissolved solids, which create high biochemical and chemical oxygen demands. Chemical oxygen demand (COD) is important in evaluating food industry wastewater quality and can help with determining the amount of organic content in wastewater. Continue reading to learn more.

Water in Food Production

Water plays a vital role in the food and beverage industry from the beginning to the end of the production processes. Water is used for soaking, chilling, blanching, cleaning, cooling, sanitizing, steaming, power, and process heating. Large amounts of wastewater must be efficiently managed during production, or else the plant’s capabilities and production volumes will be affected. Water is categorized into 4 uses in the food and beverage industry:

- General Purpose Water: Includes all water used in washing and sanitizing equipment and raw materials

- Process Water: Water used for cooking or added to the product

- Cooling Water: Water used for contact or noncontact cooling

- Boiler Feedwater: Water that is supplied to boilers for hot water or steam

Any water not used in the food production processes is considered to be wastewater and is disposed of through a drain and into a wastewater facility.

Food Production Wastewater Challenges

Depending on the food production industry, the range of waste presents different challenges. Some examples include:

- Meat and poultry: Wastewater directly discharged by slaughterhouses, further processors, independent renderers, and poultry processors

- Dairy: Wastewater from the production of milk, butter, cheese, or yogurt that uses pasteurization or homogenization

- Fruits and vegetables: Wastewater contains discarded fruits, vegetables, soil particles, pulp and fibers, cleaning agents, blanching agents, salt, and residue of pesticide

- Grain: Wastewater from grain mills that produce cereal, animal feed, wheat starch, and gluten manufacturing

- Sugar and related confectionaries: Discharge from sugar mills contain sugarcane, juice, juice concentrate, and syrup

- Fats and oils: Comes from many food types

- Beverages and brewing

In addition to the food discharge, these industries also discharge several chemical pollutants mentioned in the introduction. Each type of waste has special factors to consider, which adds to the complexity of wastewater treatment.

Sludge

One of the major components of food production wastewater is sludge. Sludge is any solid, semi-solid, or liquid waste generated from a municipal, commercial, or industrial wastewater treatment plant. Separating solids from water can generate a significant amount of sludge for disposal. Bioaugmentation actively reduces sludge volumes while increasing the aqueous phase of the wastewater stream. Less sludge saves on hauling and disposal costs because sludge must be extracted to prevent accumulation within a wastewater system.

Chemical Oxygen Demand

Chemical Oxygen Demand, or COD, is used to measure the amount of oxygen that will be consumed by the chemical breakdown in both organic and inorganic compounds. It helps gauge the short-term impact of wastewater effluent on the oxygen levels of the water and monitor water treatment plant efficiency. COD in food industry wastewater is typically high, around 1,000 milligrams per liter to 10,000 milligrams per liter, depending on the food type.

COD is measured by using a strong oxidant under acidic conditions by adding an excess amount of oxidant to the sample. Once complete, the concentration of organics is calculated by measuring the amount of oxidant remaining in the solution. The COD test occurs in just 2 – 3 hours, so it can be used as an operational adjustment parameter close to real-time and can be used to estimate the Biochemical Oxygen Demand level (BOD), which usually takes 5 days to test. Bioaugmentation can help with lowering the organic content of wastewater.

Case Study

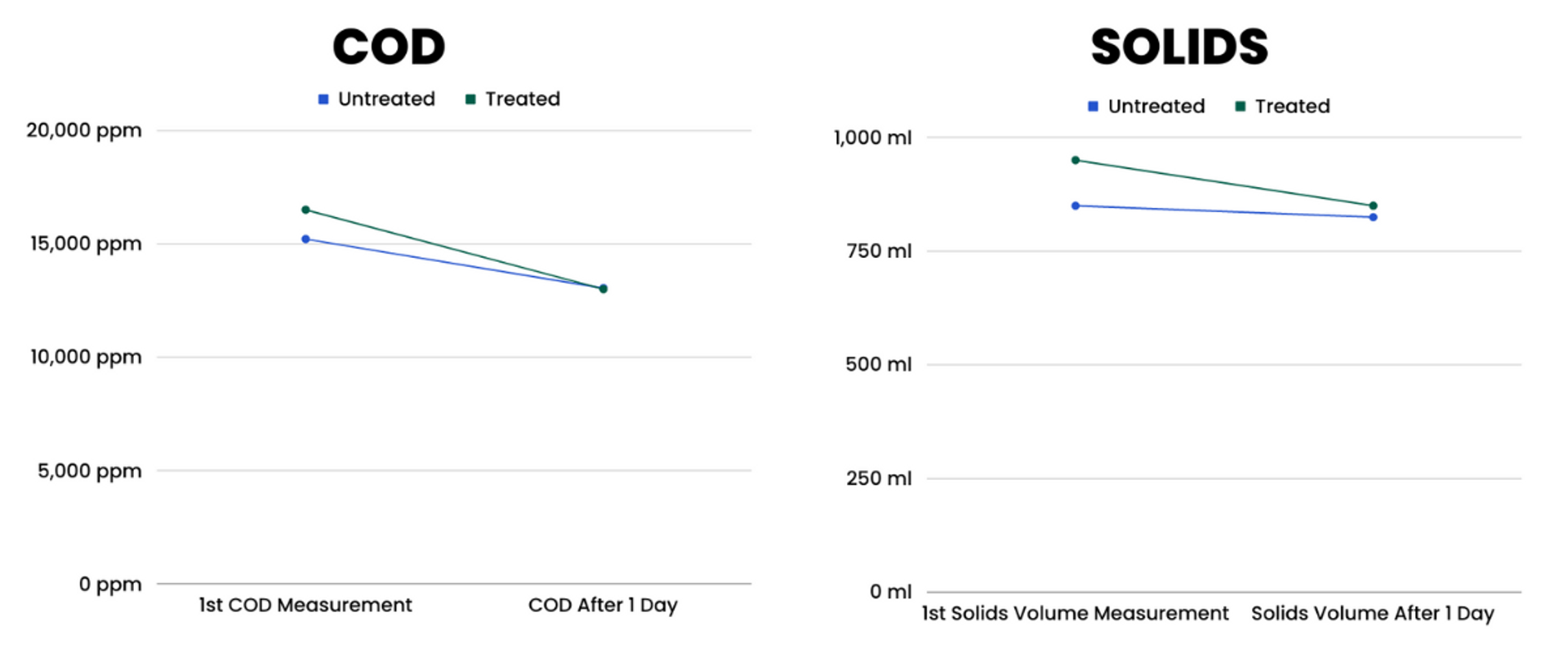

A French Fry Factory’s sludge was treated with an EnviroZyme powdered bioaugmentation product to see if sludge production decreased due to bacterial degradation and not just due to mechanical compaction. 1,000 ml samples of sludge from a French Fry Factory were stored in anaerobic conditions. One sample was treated with .37 mg of the bioactive product and .0007 mg of a nutrient blend, while the other samples were left untreated. The samples were grabbed from within the sludge layer and were monitored visually and measured for sludge volume and COD.

The Results:

Organics Control

Organics Control is a biological product formulated for augmenting the natural biology of municipal activated sludge systems and helping lower the organic content of the waste. This blend is effective under both aerobic and anaerobic conditions, providing accelerated digestion of sludge, including proteins, fats, and carbohydrates.