Phenol Control and Filament Reduction Saves $5,000 Per Day

A program was developed to meet plant goals by significantly improving the microbial community, enhancing its phenol degradation abilities, strengthening it against adverse effects of chlorination, and lowering its filamentous abundance.

Benefits

- Effluent phenol reduced consistently below 0.3 mg/L

- Reduced chlorine dioxide use for phenol destruction, saving $5,000 per day during excursions

- Reduced filamentous abundance

Background

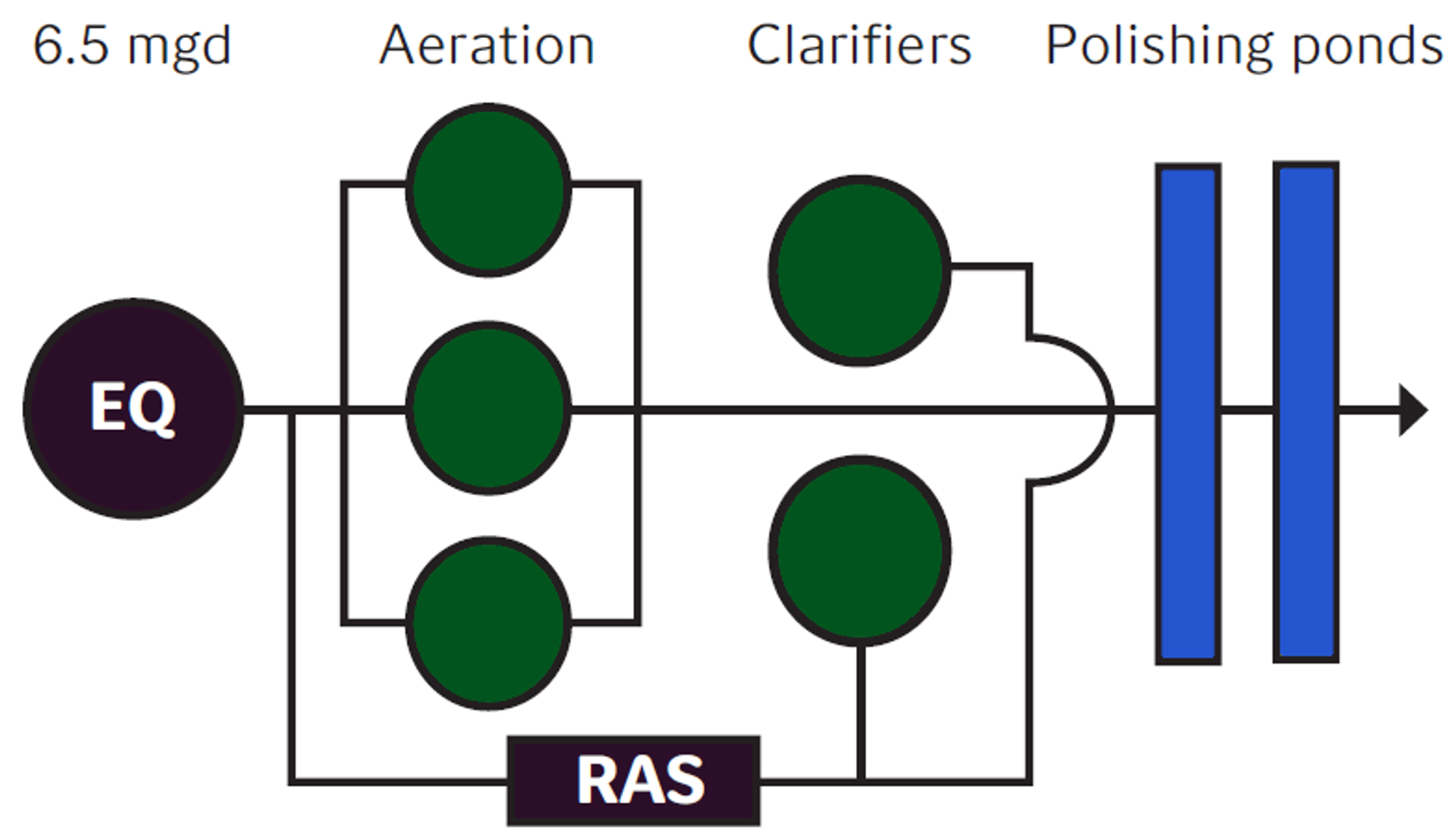

A 24.6k m3/day (6.5 mgd) refinery was having trouble reducing phenol concentrations in its effluent. When effluent phenol concentrations exceeded 0.3 mg/L, the plant was spending up to $5,000 per day on chlorine dioxide to oxidize the phenol. The plant operations team worried that these harsh chemicals were having a negative effect on the biomass. The plant was also experiencing high TSS in the effluent.

The plant was looking for a way to cut operating costs and improve plant efficiency. The plant wanted a biological solution that would provide an effective alternative to the traditional chemical solutions.

Application

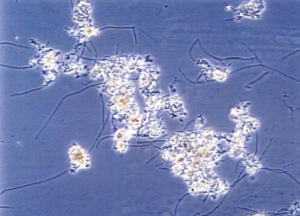

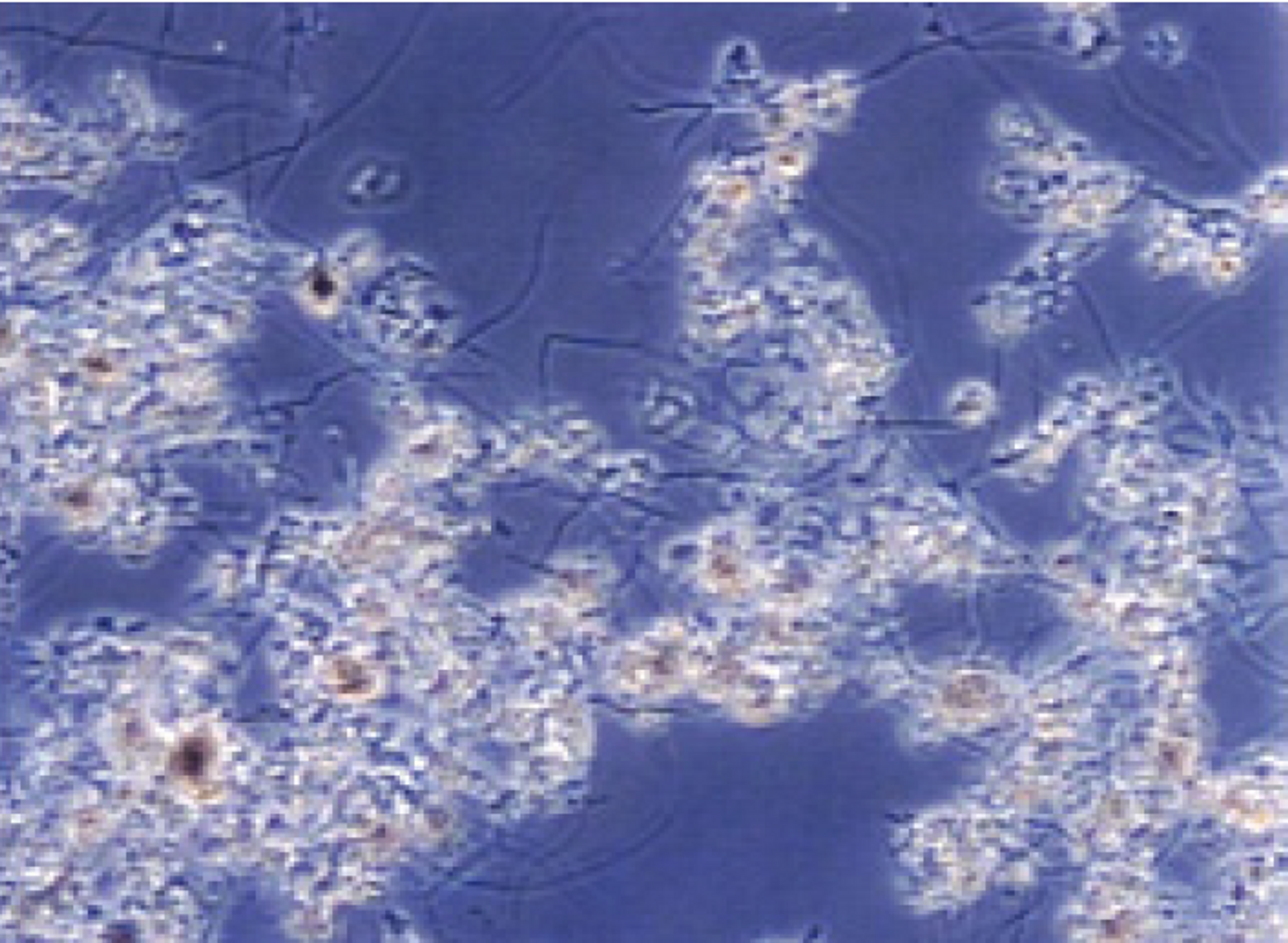

A comprehensive site evaluation was performed, and it was discovered that the existing microbial community could not consistently degrade phenol to levels below 0.3 mg/L. Furthermore, a high abundance of filaments were causing poor settling and compaction in the secondary clarifiers. Plant data and microscopic analyses were used to determine that Thiothrix I, a filamentous bacterium, was proliferating as a result of rising sulfide concentrations.

Microscopic analyses results revealed an abundance of Thiothrix I, rated as 4 (5-20 filaments per floc particle) with floc particles bridging together. Thiothrix I appeared viable and contained white sulfur granules, indicating high sulfides in the wastewater.

The typical treatment for reducing filamentous abundance is chlorinating the return activated sludge (RAS) line. However, the plant was concerned that chlorination could adversely affect the microbial community, negatively impacting phenol degradation to an even greater extent. To address both the high phenol degradation and the proliferation of filaments, a chlorination program with bioaugmentation was proposed. BioRemove Phenol was recommended to enhance phenol degradation capabilities, and BioRemove COD to help strengthen the biomass during the filament chlorination program. This blended product approach ensured sufficient COD reduction.

Results

Soon after EnviroZyme’s program was implemented, phenol levels were immediately reduced to below 0.3 mg/L. After the microbial community had been stabilized, effluent phenol concentrations were consistently maintained below 0.3 mg/L, which reduce the need for chlorine dioxide treatment altogether.

Conclusion

EnviroZyme’s biological program produced significant benefits over a strictly chemical alternative. By using BioRemove Phenol and BioRemove COD, the plant was able to lower operating costs significantly and, at the same time, maintain effluent quality. Operation of the treatment plant was simplified by improved settling, reducing the need for chemical additions. The program resulted in:

- Lower operating costs

- Improved plant efficiency

- Simplified operations